Pneumatic vs Hydraulic systems: Versa-Bar has you covered

Published on August 29, 2024

You may have heard the terms pneumatic and hydraulic, but do you know the difference between them?

Our Versa-Bar line of products provides proven results in the pneumatic and hydraulic system industries.

Versa-Bar is so good it's often called the true hydraulic metal.

The Difference Between Hydraulic and Pneumatic Systems

Understanding these two systems' differences is crucial in the industries we serve. Both are integral to many industries, but the choice depends on your specific requirements and the environment in which they're used.

In hydraulics and pneumatics, a pump acts as the actuator, with valves controlling the process of converting pressure into mechanical movement. Each system generates more force than the initial input.

HYDRAULIC SYSTEMS

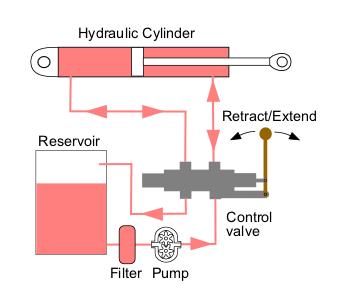

Hydraulics operate with a pressurized fluid to drive mechanical actions. These fluids cannot be compressed and transfer force from one point to another without changing the volume under pressure. Typically, a fluid like oil is used in these systems. The fluid can potentially generate up to nine times the original force.

The hydraulics systems usually consist of a series of pistons. The more pistons you add to the system, the more force and complexity it delivers. These systems deal with heavier loads and perform more work.

They often have a high initial cost, including installation expenses for permanent setups. The key to that cost is how long the system will last.

PNEUMATIC SYSTEMS

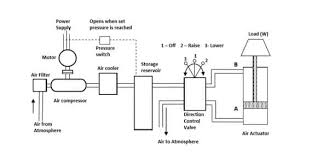

Pneumatic systems use gas instead of liquid to increase force. They consist of interconnected components, where compressed air flows through a series of hoses and is regulated by valves.

Compressed air is converted into mechanical energy. In some cases, inert gases that don't undergo chemical reactions are used for specific system tasks.

The pneumatic systems are better suited for lighter tasks, but they can also perform these at a higher speed and a lower cost.

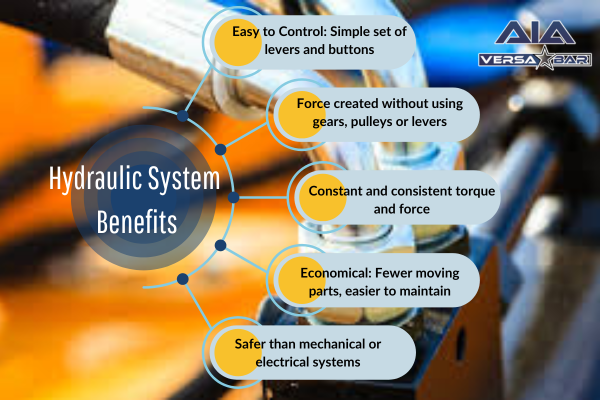

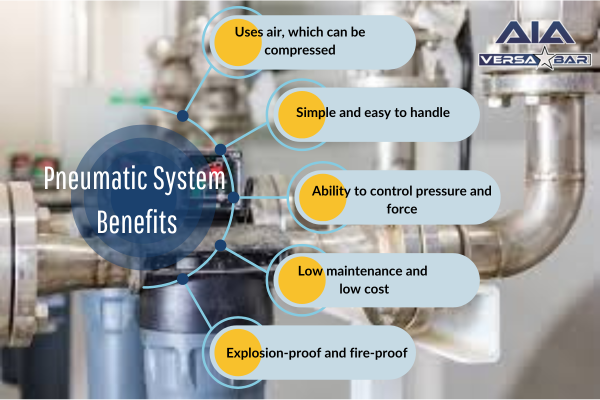

The Benefits of Each System

A Closer Look at the Pneumatic System

The pneumatic system allows you to control the pressure and force you want, while the hydraulic system only gives you minimal control.

Pneumatic systems generate force using gases, typically pressurized air. They commonly operate at around 100 psi, but some systems can reach pressures between 3,000 and 5,000 psi.

Every pneumatic system has an air compressor, which controls the pressure or force. The air is transported through hoses and valves to an actuator. One of the essential pieces of these systems is the filter, which helps prevent contaminants from entering the system.

Pneumatics can operate from a single centralized compressor running the facility. That configuration reduces the costs of repair and maintenance.

The speed of the pneumatic system must keep up with factory automation, packaging, and more. Speed is essential when loads are low. A pneumatic system helps enhance production and efficiency.

A Closer Look at the Hydraulic System

Hydraulic systems are generally large and complex.

Hydraulic systems require a lot of space for the fluid reservoirs, which need to be close to the system to support the volume of fluid required to generate the necessary pressure. This also requires the componentry to be made of heavier gauge materials with thicker walls for the tubing, pumps, and hoses.

Because the construction is more substantial, it can handle the heavier fluid pressures and carry the higher loads. However, this makes the systems somewhat slower to start and operate. Yet, it also yields smoother and more controllable maneuvers when handling large, heavy objects.

Hydraulics is the study of fluids in motion. It is transmitted uniformly when pressure is applied to a liquid within a confined space. Hydraulic systems use this principle to amplify force. This allows a seemingly small force to lift or move thousands of pounds by leveraging the pressure exerted on the fluid.

Hydraulic systems have machine-by-machine pumps and motors. They are utilized in industrial applications with pressures ranging from 1,000 to 5,000 psi. For more specialized applications, hydraulic systems can provide up to 10,000 psi.

Hydraulics have typical everyday applications. They are used in car braking systems, on airplanes to help them slow down and land, and even in trash compactors and garbage trucks.

Turn to Versa-Bar for your hydraulic or pneumatic part needs

We can deliver high-quality parts for hydraulic and pneumatic systems.

With our continuous cast iron, we make quality parts like cylinders, iron pipes, and various valves. Those valves include check, flow control, and directional.

Why choose Versa-Bar for Fluid Power Applications?

The Versa-Bar continuous cast iron features microscopic flakes or graphite spheres with tiny recesses that help retain oil. This means lubricated parts stay oily longer, and the graphite acts as a self-lubricant in case of oil loss. Versa-Bar tubes, rounds, bars, and rods offer superior wearability.

Versa-Bar is used in hydraulic systems for pistons, glands, manifolds, valves, pump housings, and vanes.

Versa-Bar is used in compressor screw rotors and vane-type rotors in pneumatic systems.

Our fast and flexible nationwide supply chain allows us to provide your fluid power components consistently. We only need a blueprint with your specifications for custom hydraulic and pneumatic components to start building a prototype.

We aim to provide you with the highest-quality hydraulic and pneumatic parts at the most affordable price. We also make sure you get them when you need them.

Versa-Bar's capabilities extend far beyond replacement fluid power parts. Our precision CNC machining service allows us to manufacture various metal parts for multiple applications.

Click here to learn more about our Versa-Bar products, or get a quote today.

Resources/References