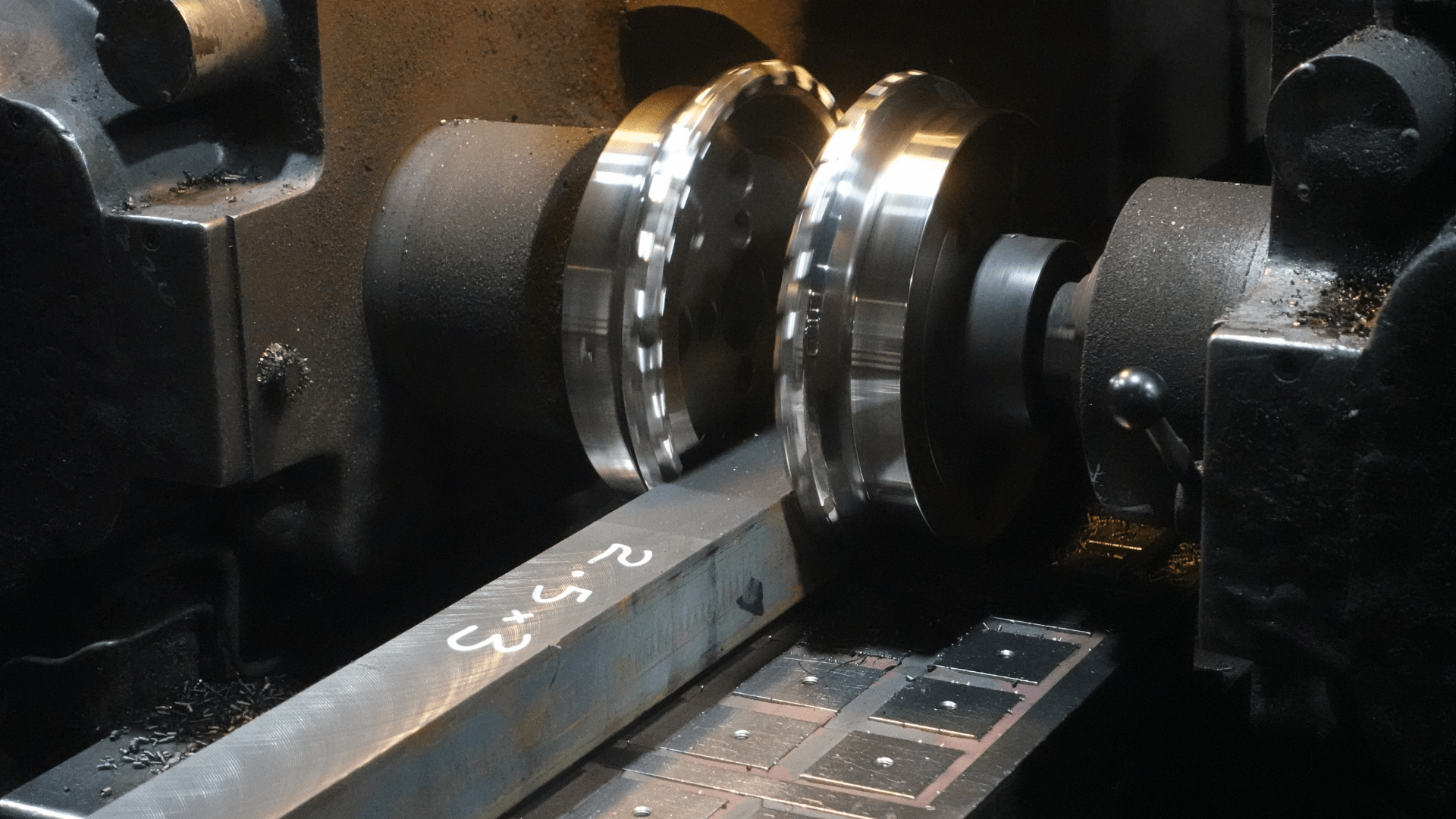

Precision CNC machining services in Waukesha and nationwide

Reduce production time with CNC machining

Pre-machined or finished, we provide value-added processing services to save you time and money. Logistical savings are at the core of our machining division. Pairing our precision CNC machining services with the savings from our mill-direct metal supply means lower transportation costs, less on-hand inventory, and reduced manufacturing costs for you. We offer a range of machining capabilities for various industries, including automotive and racing, fluid power, foundries, aerospace, and many others.

We're based in Waukesha, WI, and serve as the number one metal and machining service provider for locations across the United States. Our broad distribution capabilities extend our reach nationwide, allowing us to serve wherever you are. Whether you need raw materials or fully machined metal components, you can customize your supply program.

- Bettervolume pricing

- Flexible supply program

- Quick nationwide supply chain

Value-added rough processing and machining services

Our CNC machining services are a beneficial addition to our Versa-Bar continuous cast iron products. Adding precision machining to your metal products reduces production time and helps you get the job done faster. We provide durable, custom-machined components for a wide range of industries, from large to small. Let our machining experts reduce your sourcing time and machining costs with high-quality metal products. Rough machining services include:

- Turning

- Boring

- Pre-Milling

- Plate Cutting

- Precision CNC Horizontal Machining

- Precision CNC Vertical Machining

Our CNC machine shop has a large facility capable of producing large and small orders of machined components. We have various machine tools in-house to provide you with dependable rough processing and finish machining services. The machine list includes:

- 6 CNC Horizontal Lathes

- 3 Manual Turret Lathes

- 2 CNC Vertical Machining Centers

- 3 Duplex MKCS (9' Beds)

- 8 Automatic Cut-Off Saws

- 1 Automatic Precision Cold Saw

- 4 Plate Saw (10' bed)

- 3 Automatic Chucker Lathes

CNC tool grinding, vertical, and horizontal machining

Using modern CNC tool grinders and our specific manufacturer’s capabilities, we provide businesses nationwide with advanced CNC grinding services. We can produce a variety of custom metal products and tools, including those for metal cutting and woodworking.

We provide all our customers with high-precision CNC vertical and horizontal machining. We can take on large quantities of work to accurately machine your CNC products. No matter how demanding or specific your requirements are, we machine various iron and bronze materials into products worth the investment.

Precise CNC turning services

Turning is just one of many processes our advanced CNC machine shop in Waukesha, WI, can perform with impeccably high precision. Bearings, bushings, pistons, wear plates, pulleys. You name it; we machine it.

As members of Lawton Standard, we can offer our customers many machining options nationwide.

New lower-cost and performance options help save you money and guarantee your products will work and be finished better than other companies offering the same CNC turning services. We have many products available online for your convenience, including raw bronze stock and custom-finished bronze components. AIA Versa-Bar Lawton Standard has turned and finished machined bronze bushings, washers, and bearings for years. Contact us today for a free CNC turning and bronze tubing options quote.

More on Turning

Custom boring machining services

Whether your business is in Waukesha, Wisconsin, or another state, Lawton Standard makes metal supply easier with boring and custom metal products and services. We have you covered if you have a metal product with a hole already on its surface but need it enlarged at a money-saving price. By choosing our services and products, you quickly add value to your line of products and merchandise. We process and complete raw cast metals and boring services quickly and precisely at a low price every time. You are taken care of with our top-of-the-line manufacturing capabilities.

More on Boring

Top precision pre-milling services

As the leading supplier of pre-milling services and precision engineering, we help reduce your project’s production time and spending budget for higher efficiency. Get a quote on pre-milling, raw metal, finished, and machined metal components. We can serve the machine tool, construction, and off-highway equipment industries. Our precision engineering services are one of the most comprehensive in the state.

In addition to being convenient, our precision engineering and pre-milling services are customizable, making your supply program even more specific and relevant to your needs.

More on milling >>

CNC plate-cutting services

As Waukesha, Wisconsin’s best plate cutting and custom casting fabricator, we can cast components made to your specifications and perform efficient CNC plate cutting. In our CNC shop, you can expect the highest-quality custom metal parts. We can easily provide you with hard-to-source sand casting and cast metal bar special shapes.

Our partnerships save you money. We cut and cast iron, bronze, and steel parts without outsourcing to another machine shop. Get a quote on specialty castings and your options regarding our manufacturing capabilities.

More on CuttingMetal cutting services nationwide

We have your solution for reliable and affordable advanced metal-cutting services. We'll provide an industry-best price quote based on the size and number of metals you need cut.

Utilizing Versa-Bar, our company has access to the best metallurgically superior steel alternative on the modern market, meaning our custom-cut components outperform those of any competing product. If you need a metal supply partner, consider partnering with us for high-quality metal, precision CNC machining, and a reliable supply chain. We service more than just the Milwaukee area. We distribute across the US, including:

- New York

- North Carolina

- California

- Texas

- Illinois

- Milwaukee, WI

- Chicago, IL

- Los Angeles, CA

- Houston, TX

- Madison, WI

- Pearland, TX

- Portland, ME

- Jacksonville, FL

- Baltimore, MD

- Sugar Land, TX